Recycling

Reprocessing is the process of using those waste plastics or by-products that were generated during the manufacturing of plastic materials, while Recycling is the process of treating the once-consumed plastic materials in such a way that they could be again used in the production of further Plastic materials. Reprocessing is a multistep process that includes cleaning, inspection, assembly, functional testing (if applicable), packaging and labeling, and storage.

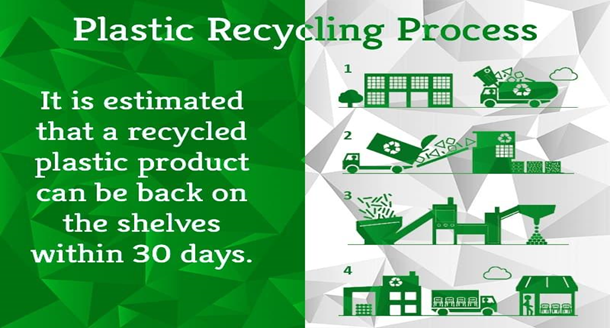

Recycling is a process that involves collection, sorting, washing, resizing, identification, and compounding. The first step in polymer recycling is the collection of waste polymers that are to be processed for recycling.

Advantages of Recycling

- It Conserves Energy

- Reduces Air and Water Pollution

- Reduces Greenhouse Gases

- Conserves Natural Resources.

- Facilitates Circular Economy

Reduce

It emphasizes the reduction of non-essential usage of plastics to the best possible extent we can. For instance, soft plastics are often impossible to recycle because they get caught in moving machine parts, causing them to get stuck. We can expedite the feasibility of switching over to a harder plastic like PET, which can be recycled.

Recycle

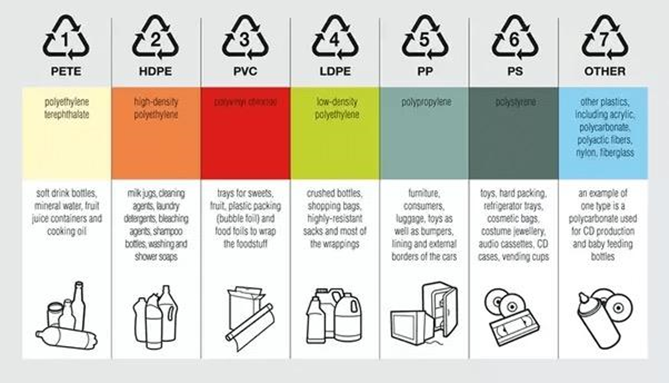

Despite the complexity of this process, nevertheless, we can make the “Best” from “Waste”, It all begins with sorting the plastic by type. There are seven types of plastics, as shown below:

Steps involved in Plastic Recycling

Recycling is the foundation of a circular economy in the global scenario (i.e., retaining the value of plastic waste in a reusable form in the economy without causing harm to the environment). A circular economy is restorative and regenerative, which implies that plastic materials constantly flow around a “closed loop” system rather than being used once and then discarded, polluting the environment.

Having identified selective sectors, with the key driver being the packaging segment, WE at Plasmix are mobilizing our best resources by providing masterbatches to ensure that the highest degree of plastic in the packaging segment is being recycled. To facilitate such a formidable task, major challenges are emerging in terms of the sorting of waste to produce a high-quality Post-consumer recyclate (PCR) and issues related to stabilization, coloration, safety, and processing.

As we are committed to offering our customized solution for PCR, we bring our utmost knowledge and experience gained over more than three decades in various applications and market segments to overcome the challenges and harness the opportunities in the new era. We have established our full-fledged dedicated Team comprising production, R&D, Technical support, and Salesforce to understand the recycling market dynamics and remain at the forefront of products and solutions that increase the quality of PCR by all means.

We have already developed our products through our cutting-edge technology, offering colorants and additives from our range that prevent damage or loss of performance properties during recycling and others that repair the damage that inevitably occurs as polymers are processed, used, and then reprocessed, facilitating the circular economy. Our products are