Improved Processability

Our masterbatches are designed to optimize melt flow, ensuring smooth processing and reducing production downtime due to issues like die build-up or machine wear.

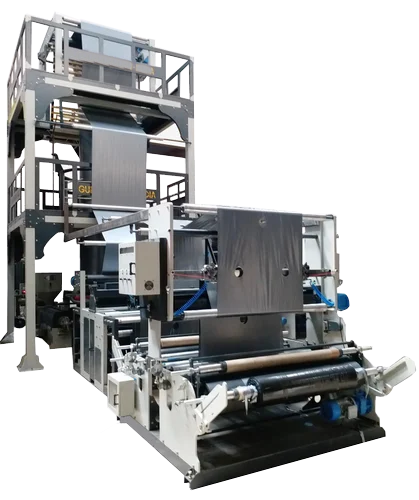

At Plasmix, we provide specialized masterbatches for a wide range of extrusion applications, ensuring that our clients can achieve superior product quality, improved processing efficiency, and cost optimization. The extrusion process is critical for producing continuous lengths of plastic products used in various industries.

Extrusion is a high-volume manufacturing process where raw plastic material is melted and formed into a continuous profile. The process involves pushing the melted plastic through a die to create shapes such as pipes, sheets, films, and profiles. These extruded products are then cooled and cut to size for further use or assembly.

Extrusion is widely used in various industries, including construction, automotive, packaging, and consumer goods, making it a fundamental process in plastic manufacturing.

Our masterbatches are designed to optimize melt flow, ensuring smooth processing and reducing production downtime due to issues like die build-up or machine wear.

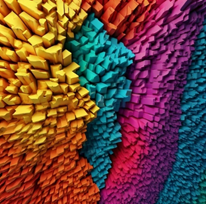

We offer a wide range of Colour masterbatches that deliver consistent, vibrant, and stable Colours, ensuring a premium appearance for extruded products.

Using our filler masterbatches can reduce material costs by replacing a portion of the polymer with lower-cost fillers without compromising on performance.

Our Colour masterbatches ensure uniform dispersion, providing consistent and vibrant Colours across the entire extrusion output.

Our masterbatches enhance the barrier properties, clarity, and strength of Biaxially Oriented Polypropylene (BOPP) films, making them ideal for food packaging and consumer goods.Solutions include anti-static, anti-fogging, and slip additives for high-performance packaging films.

We provide specialized Colour and additive masterbatches for the extrusion of monofilament and multifilament yarns used in textiles, fishing nets, and ropes.Our solutions improve UV resistance, enhance tensile strength, and offer excellent Colour fastness.

Our masterbatches are widely used in the extrusion of pipes, conduits, and profiles, offering superior impact strength, UV stability, and weather resistance for long-lasting construction products.

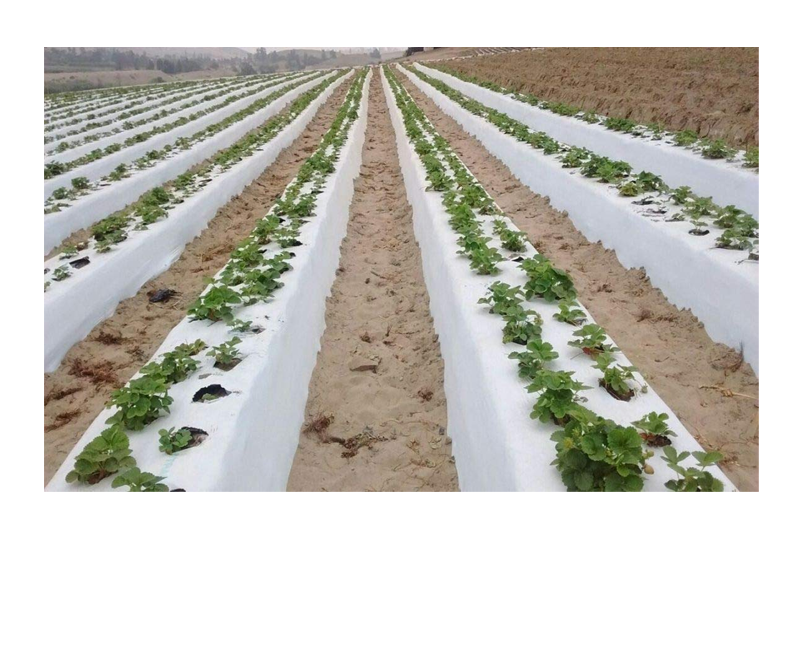

For agricultural applications like mulch films, greenhouse covers, and irrigation pipes, our masterbatches improve UV resistance and chemical resistance, extending product lifespan in harsh outdoor environments.

Flame-retardant and anti-static masterbatches for cable extrusion ensure high safety standards. Our solutions also provide UV resistance and insulation stability for long-term electrical applications.