Construction And Infrastructure

Masterbatches are essential to the construction and infrastructure sectors because they provide a variety of advantages and functions for a variety of building materials. To improve the performance, tensile strength, and aesthetic appeal of plastics, coatings, and other building materials, specialized additives are added. Here are a few significant uses for masterbatches in the building and infrastructure industries.

TYPICAL PLASTICS PRODUCTS USED IN

CONTRUCTION AND INFRASTRUCTURE SEGMENTS ARE:

TRAFFIC BARRICADE

CONSTRUCTION PIPE

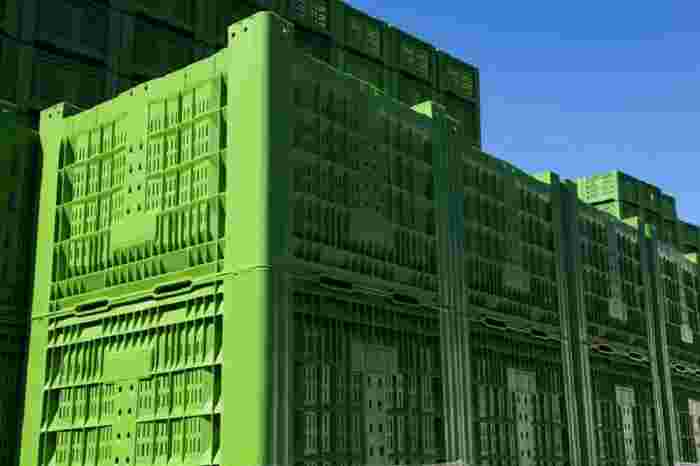

MOULDED TRANSPORT CONTAINERS

CONSTRUCTION TOOLS

SAFETY GEAR

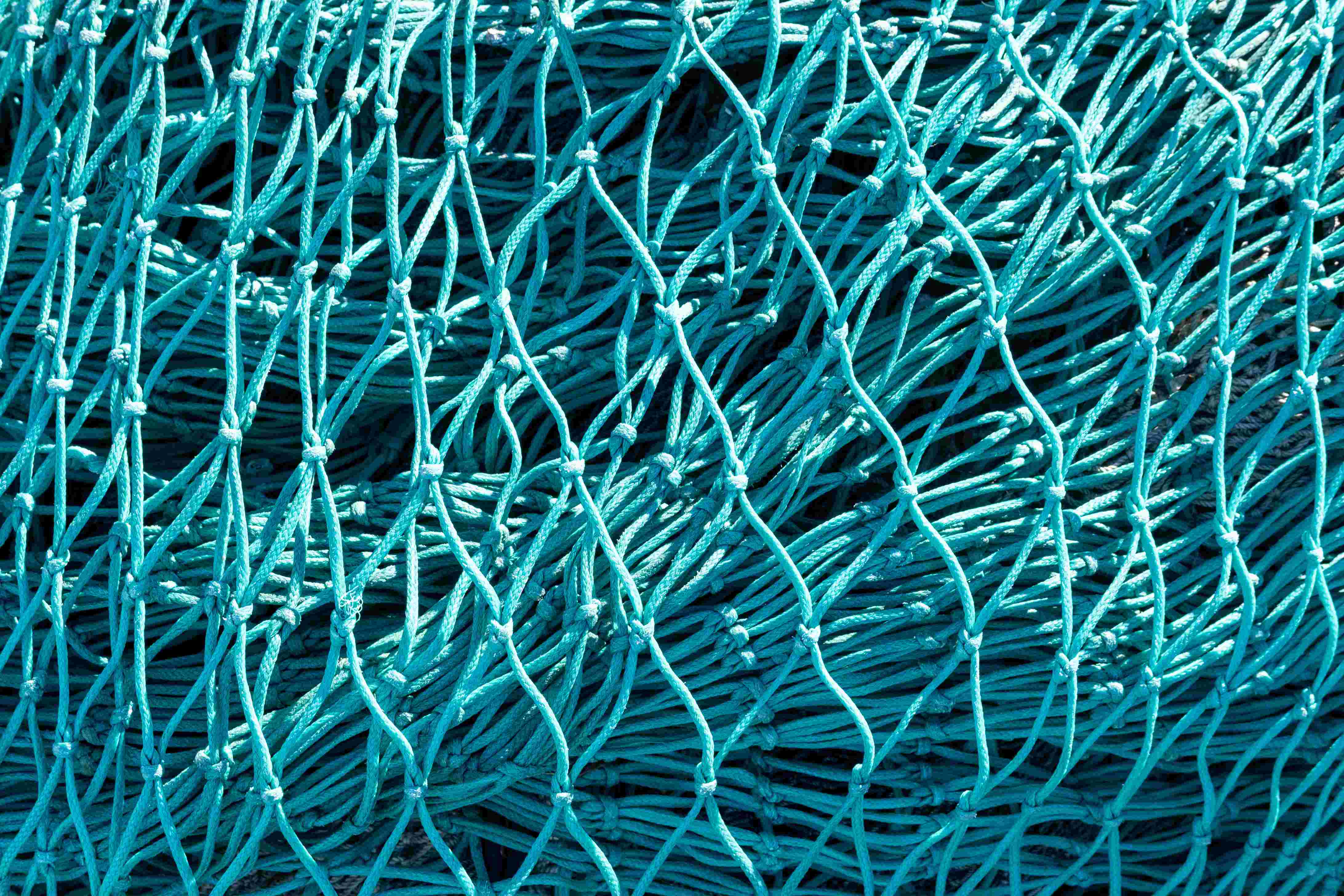

CONSTRUCTION NET

Colour and Aesthetics

To achieve vivid and consistent Colours in a variety of building materials, Colour masterbatches are widely employed in the construction industry. Colour masterbatches provide a wide range of Colours to complement architectural designs and aesthetic preferences, whether it be for Coloured plastics, coatings, or concrete. They contribute to the creation of aesthetically pleasing structures, increased brand recognition, and improved overall construction project aesthetics.

UV Resistance

UV stabilizer masterbatches are added to construction materials to strengthen their resistance to UV radiation. These masterbatches protect plastics, coatings, and other materials from the detrimental effects of sunlight, such as Colour fading, deterioration, and reduced strength. In outdoor applications like window frames, roofing materials, façade claddings, and outdoor furniture, UV-stabilized building materials are frequently utilized to ensure long-term durability and aesthetic integrity.

Flame Retardancy

To increase the fire resistance of construction materials, flame retardant masterbatches are added. By preventing or decreasing the spread of flames, these additives lower the danger of fire mishaps and improve building security. To provide essential fire safety in both residential and commercial structures, flame retardant materials are widely employed in applications such as electrical enclosures, insulation products, piping systems, and interior furnishings.

Anti-static and Conductive Properties

Masterbatches with anti-static and conductive properties are utilized in building materials to control static electricity and disperse electrical charges. Anti-static additives that stop the accumulation of static charges decrease the likelihood of electrostatic discharge (ESD) events and the attraction of dust or particles. Applications requiring electrical conductivity, such as flooring, safety mats, and electromagnetic shielding, use conductive masterbatches.

Weatherability and Durability

Masterbatches can increase the wearability and durability of building materials, making it possible for them to survive adverse weather conditions as well as protracted exposure to moisture, chemicals, and temperature changes. The durability of building materials is ensured by these additives, which increase resistance to deterioration, cracking, and discoloration. Masterbatches that are resistant to the elements are frequently used in waterproofing systems, decking, and external coatings.

Anti-graffiti and Easy Cleaning

Construction materials can be given anti-graffiti qualities via masterbatches, rendering them impervious to paint, ink, and other graffiti-causing chemicals. These additives produce a protective surface that makes it simple to remove graffiti, cutting down on maintenance expenses and maintaining the aesthetic appeal of buildings. Furthermore, masterbatches with easy-cleaning qualities make it easier to remove dirt, stains, and pollutants from surfaces, making them appropriate for use in high-traffic or polluted locations.

Our Masterbatch Solution For Construction And Infrastructure Applications

| SrNo | Masterbatches | Products |

|---|---|---|

| 1 | Colour Masterbatch | PM 1829 TANK G YELLOW |

| PM 2286 GREEN TONE WHITE | ||

| PM 2791 TEAL BLUE | ||

| PM 3331 TANK GOLDEN YELLOW | ||

| PM 3587 LIGHT BEIGE | ||

| PM 3659 BLUE | ||

| PM 3744 BLUE | ||

| PM 1394 LEMON YELLOW | ||

| PM 1227 GOLDEN YELLOW | ||

| PM 1340 ORANGE | ||

| PM 1392 PINK | ||

| PM 1685 PARROT GREEN | ||

| PM 1782 LEMON YELLOW | ||

| PM 2076 BROWN | ||

| PM 2908 PINK | ||

| PM 3356 ORANGE | ||

| PM 1014 G YELLOW | ||

| PM 2328 GOLDEN YELLOW | ||

| PM 3667 GOLDEN YELLOW | ||

| 2 | White Masterbatch | PM 9213 WHITE |

| PM 9083 MILKY WHITE | ||

| PM 9184 BT WHITE | ||

| PM 9287 WHITE | ||

| PM 9228 WHITE | ||

| PM 9013 WHITE | ||

| PM 9236 MILKY WHITE | ||

| PM 9244 BT WHITE | ||

| PM 9296 NEW MILKY WHITE | ||

| PM 9013 WHITE | ||

| PM 9228 WHITE | ||

| PM 9256 WHITE | ||

| PM 9000 WHITE | ||

| PPM 9004 WHITE | ||

| 3 | Filler Masterbatch | PM 3497 MILKY OMEGA |

| FILLED PP (TUFF PLAS) | ||

| FILLED PP (FAB MIX) | ||

| 4 | Black Masterbatch | PM 3450 SPECIAL BLACK |

| PM 3451 SUPREME BLACK | ||

| PM 3453 DELUXE BLACK | ||

| PM 3618 BLACK | ||

| 5 | UV Masterbatch | PM 3467-UV FDL 20% |

| PM 3466-UV MASTERBATCH | ||

| UV MASTERBATCH 20 % | ||

| 6 | Additive Masterbatch | PM 3463 PPA MASTERBATCH |

| STIFNER |