Automotive and Transportation

In the automotive and transportation sectors, masterbatches are important because they provide a variety of advantages and functionality for different parts and materials used in cars. To improve the performance, appearance, and functionality of plastics, coatings, and other automotive materials, these specialized additives are used. Masterbatches are widely used in the automotive and transportation industries for the following reasons.

TYPICAL PLASTICS PRODUCTS USED IN

AUTOMOTIVE AND TRANSPORTATION SEGMENTS

FRONT BUMPER

REAR BUMPER

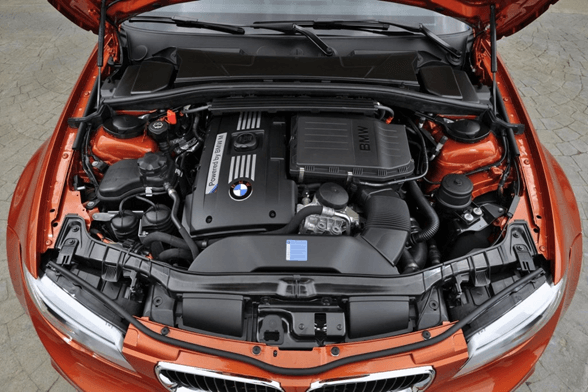

COMPARTMENTS

MUDGUARD AND OTHER TRUCK PARTS

BIKE PARTS

ELECTRIC VEHICLE PARTS

Colour and Aesthetics

To achieve vivid and consistent Colours in various car components, Colour masterbatches are widely employed in the automobile industry. Colour masterbatches offer limitless customization options for anything from exterior body elements to interior trim pieces, enabling automakers to design aesthetically appealing automobiles that are consistent with brand identity. They contribute to the appeal and market placement of the vehicle by enhancing the overall aesthetics and visual impact of automobile designs.

UV Resistance

Automotive materials are treated with UV stabilizer masterbatches to increase their resistance to UV light. These masterbatches shield polymers, coatings, and other materials against the degrading, weakening effects, Colour fading, and other negative impacts of sunlight. Exterior trims, bumpers, and mirror housings that have undergone UV stabilization remain durable and aesthetically pleasing even after extended exposure to sunshine.

Scratch and Wear Resistance

Masterbatches can be used to increase an automobile material's scratch and wear resistance. Scratch-resistant chemicals produce a shield of protection that lessens the sight of surface blemishes and scuffs, preserving the beauty of the dashboard, door panels, and interior trim elements. Surfaces that are frequently in contact and prone to friction, such as seating materials, armrests, and steering wheels, can last longer when they are coated with wear-resistant masterbatches.

Flame Retardancy

To increase the fire resistance of automobile parts, flame retardant masterbatches are used. In the case of a fire, these additives prevent or slow the spread of flames, enhancing passenger safety. To ensure that the vehicle complies with strict safety requirements and regulations, flame-retardant materials are frequently utilized in wire harnesses, engine compartments, and interior fabrics.

Anti-static and Conductive Properties

Automotive materials are utilized to regulate static electricity and disperse electrical charges using masterbatches with anti-static and conductive properties. Anti-static additives that stop the accumulation of static charges decrease the likelihood of electrostatic discharge (ESD) events and the attraction of dust or particles. Applications for conductive masterbatches include electronic connectors, EMI/RFI shielding, fuel systems, and other components that need electrical conductivity.

Weight Reduction

Masterbatches can help with weight reduction initiatives in the production of automobiles. Vehicles can achieve higher fuel efficiency and lower emissions by adding additives that enhance the performance and strength of lightweight materials like thermoplastics and composites.

Weatherability and Durability

Masterbatches can improve the materials used in automobiles' weather ability and durability, making it possible for those materials to survive abrasive weather, extreme temperature changes, and chemical exposure. By strengthening resistance to fading, cracking, and deterioration, these additives make exterior parts like bumpers, grilles, and mirror housings continue to look good and remain structurally sound over time.

Our Masterbatch Solution For Automotive and Transportation Industry

| SrNo | Masterbatches | Speciality Additive | Compounds |

|---|---|---|---|

| 1 |

All colour masterbatches Black Masterbatches,White Masterbatches,Marble effect masterbatches, Pearlcent Masterbatches,Transperent masterbatches and Filler masterbatches |

Anti- scratch | Flame Retardant Compound |

| 2 | Anti-Fog | CaCo3/Talc Filled Compound | |

| 3 | Long Freshness Masterbatches | Glass Filled compounds | |

| 4 | UV Masterbatches | PVC Compounds | |

| 5 | PPA Masterbatches | ||

| 6 | Optical Brightner | ||

| 7 | Anti-slip and Slip Masterbatches | ||

| 8 | Odour Removal Masterbatches |