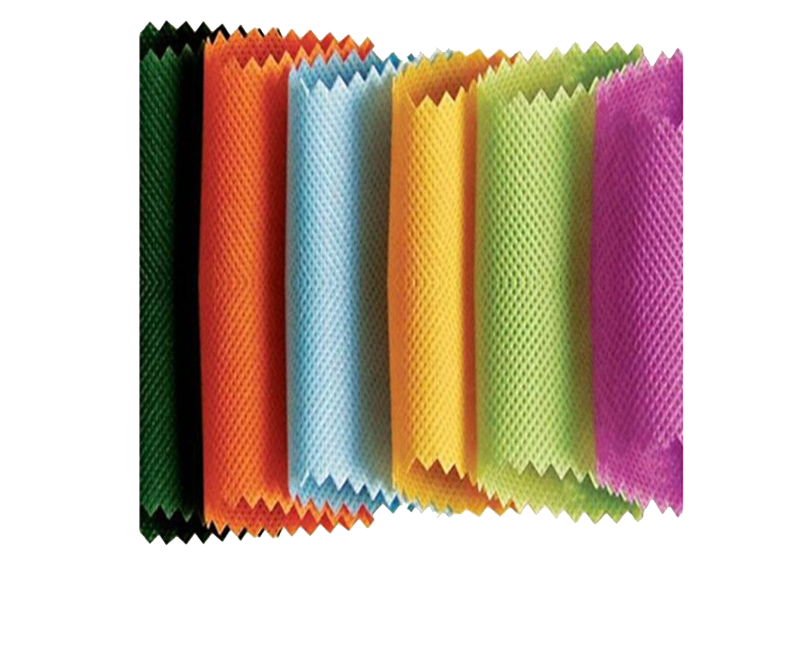

Consistent and Vibrant Colours

With Plasmix Colour masterbatches, manufacturers can achieve vibrant, uniform Colours across production batches, ensuring consistency and aesthetic appeal in products like packaging materials and medical supplies.

At Plasmix, we specialize in manufacturing high-performance masterbatches that enhance the properties of non-woven fabrics used across diverse industries. Our masterbatches are formulated to provide superior Colour, strength, and functionality, ensuring that non-woven materials meet the stringent requirements of industries such as medical, hygiene, agriculture, construction, automotive, and packaging. With years of experience and a commitment to innovation, Plasmix offers solutions that improve production efficiency, product quality, and cost-effectiveness for non-woven applications.

Non-woven fabrics are increasingly used in various sectors due to their versatility, lightweight nature, and durability. Unlike traditional woven materials, non-woven fabrics are made by bonding or entangling fibers through heat, chemical, or mechanical processes, creating a fabric that is both functional and affordable.

With Plasmix Colour masterbatches, manufacturers can achieve vibrant, uniform Colours across production batches, ensuring consistency and aesthetic appeal in products like packaging materials and medical supplies.

Plasmix masterbatches enhance the softness and pliability of non-woven fabrics, making them suitable for sensitive applications like hygiene and medical products.

For outdoor applications, such as agricultural ground covers or geotextiles, our UV-stabilized masterbatches provide long-lasting protection against degradation from sunlight, ensuring durability in harsh environments.

Our masterbatches are optimized for high filler loading, allowing manufacturers to reduce costs while maintaining or even improving the functional properties of their non-woven materials.

Applications: Face masks, gowns, surgical caps, drapes, and disposable medical products.

Plasmix Solution: Our masterbatches ensure high levels of hygiene and sterility, with anti-bacterial properties and compliance with medical industry standards. They also offer superior fabric strength for extended use in critical applications.

Applications: Diapers, sanitary napkins, adult incontinence products, and wet wipes.

Plasmix Solution: We offer soft, flexible masterbatches that improve comfort while ensuring high absorbency and fluid barrier properties essential for hygiene products.

Applications: Ground covers, mulch fabrics, plant protection sheets, and seed blankets.

Plasmix Solution: Our masterbatches are UV-stabilized to withstand prolonged exposure to sunlight, while also providing strength and breathability, ensuring long-lasting protection in agricultural environments.

Applications: Geotextiles, roofing underlayment, insulation, and moisture barriers.

Plasmix Solution: Plasmix masterbatches offer excellent mechanical properties like strength, water resistance, and UV protection, critical for non-woven applications in construction.

Applications: Upholstery, carpeting, soundproofing, and thermal insulation.

Plasmix Solution: Our masterbatches are tailored to enhance heat and sound insulation while maintaining durability and flexibility, ensuring non-woven fabrics meet automotive industry standards.

Applications: Reusable bags, protective packaging, and absorbent liners.

Plasmix Solution: We provide masterbatches that offer superior tear resistance and flexibility, while also allowing for customization in Colour, ensuring non-woven packaging products are both functional and aesthetically pleasing.