Transparent / Talc Masterbatches

Transparent / Talc Masterbatches

Talc Filler masterbatches is self-possessed of talc powder, base resin, and supportive additives. This is considered an ideal filler for plastic. This is because we can improve productivity while reducing production costs. A plastic masterbatch containing talc powder can be used to replace a part of primary plastic. This is a wonderful solution that saves raw materials while limiting the amount of crude oil.

For those looking to connect with the best Talc Filler manufacturers in all over india, Plasmix Pvt.Ltd would be the right choice. Plasmix Pvt.Ltd is the leading manufacturer and exporter of various masterbatches. We create products that cater to our customers’ current and future needs for both standard and specialty solutions.

Special Properties of Talc Masterbatches

The reason talc is so popular as a plastic filler is due to its exceptional qualities:

- Substantial Softness: Talc is also known with another name – “soft stone” as this material’s rigidity is relatively low compared to that of others. This advantage allows plastic products containing talc to be printed easily on the surface, thus making talc the first priority in many fields such as sculpture, household appliance production.

- Inertness: Unlike other substances which might cause allergy for humans when they have skin contact, talc powder is quite safe, making it an indispensable component in cosmetic production. Besides, this characteristic also gives talc filler a plus point when it is mixed with other matters as it hardly afflict their properties.

- Aid in Processing: Seems a bit surprised but talc powder can assist in processing procedure. Thanks to its low hardness, the processing of plastic filler talc remarkably minimizes abrasion on equipment than harder materials, especially in extrusion.

- Thermal Reactivity: Talc particle’s platy shape increases the heat resistance as well as reducing shrinkage, thus it is especially suitable for laboratory tabletop surfaces, sinks and countertops. Also, this material enhances end-products’ rigidity such as polypropylene, vinyl, polyethylene, nylon, and polyester.

Common Applications Of Talc Masterbatches

Blow Films

Plastic filler talc is an indispensable component of packaging films such as shopping bags, food packaging films, single-use food box, waste bags etc.We can offer wide range of Colours from our existing product range

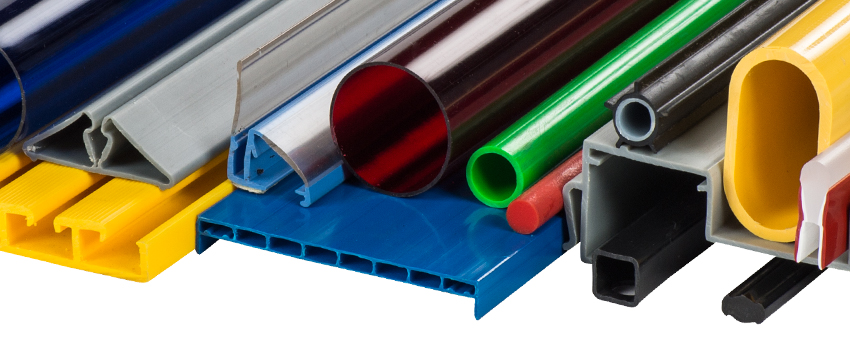

Extruded

Another common application of plastic filler talc is definitely extrusion with various products such as pipes, blinds, clear compounds, fencing, interior profiles, planks and sheets.

Injection Molding

Injection molding products such as glass, plates, bowls, knives, folks, spoons,…also use talc filler as an important filler enhancing stiffness, thermal resistance and durability.

TPT

Talc filled LLDPE Based masterbatch and developed for Lamination of Woven Sacks Bag and other products by applying the reinforcing properties of ultrafine Talc & carrier resin with higher M.F.I. to provide the better mechanical properties to the product.

TPT V80

Talc filled LLDPE Based masterbatch and developed for Lamination of Woven Sacks Bag and other products by applying the reinforcing properties of ultrafine Talc & carrier resin with higher M.F.I. to provide the better mechanical properties to the product.

CLEAR TPT

Na2SO4 (sodium sulfate) filler masterbatch is one kind of high-end quality filler. They use this filler mainly for superior PE, PP packing materials.

Specification of Transparent / Talc Masterbatches

Another advantage is that the talc filler will greatly improve the plastic properties thereby helping the plastic output products have a higher value in the consumer market. Connect with us today and fulfill your requirements!

| Form | Granules |

| Packaging Size | 25 kg |

| Packaging Type | Bag |

| Is it Recyclable | Yes |

| Colour | White |

| Usage/Application | Injection Molding |